ECONOMICAL STORM FUEL INJECTOR FOR ANY KIND OF FUEL ENJECTION SYSTEM

Dudeshev

Russian Federation

ecolog@samaramail.ru

cell 89277262383

In Russian Federation was developed and patented a unique Storm Fuel Injector which would be useful

for any kind of transport vehicles that have an injection fuel system. This injector is designed to increase

power of an engine as well to reduce amount of fuel usage. Time for installation would take about 15

minutes and it does not require specific knowledge to do so. This device is designed and developed to

better mix fuel and air before it will burn in the combustion chamber of the engine. The efficiency is

about 100%. Therefore, at this point we would have more efficiency in the burning processes and

apparently would save fuel and would have more power at the same time. According to the test results

we would have up to 20% more of power and less toxic gases for up to 20 times. It would be a revolution in usage of the device because people need such an invention which would

reduce expenses for the fuel usage and decrease its negative impact on the environment at the same

time. It would bring a financial success in all business aspects. It would have success to obtain in the

public level or/and the first stage of manufacturing motors. We are looking for business partners and

investors at this time.

General View at the problems in Automotive Industry. This is a fact that people need vehicles. Nevertheless, the truth is that Combustion Motors which we still

use in our cars are primitive and have low capacity in the way of using energy of burned fuels. The

capacity of the modern engine type is not higher than 20% in average. In many cases the low economical qualities of motors are low just because of low quality of BLENDED

fuels with the air. Is that would be possible to increase the capacity of the modern engine? The answer

is YES. Moreover, we can do just by simple electro-mechanical device called Storm Fuel Injector. Let us

talk about it.

GENERAL TECHNICAL AND ECONOMICAL QUALITIES OF THE STORM FUEL INJECTOR As we know, fuel injection systems have more efficiency rather than carburetor fuel ones. The computer

control portions of fuel and optimizes processes of mixing fuel and air as well as quantities of the

mixture depending of working stage of the engine at that time. Nevertheless, fuel injectors by itself are

not so efficient and would not create the perfect fuel spray into the chamber. Therefore Intake system is

not as efficient as it may be. In many cases fuel injectors are placed too close to the intake valves of the

system and process of spray would be hard to classify as a perfect way of spray. That is the reason why

systems are not so efficient at this matter. The mixture of fuel and air cannot be burned for 100% of its

volume and some part of the unburned fuel just goes into the muffler system and out to the

atmosphere. That is why we see low efficiency of the engines and low economy budget. Higher use of

fuel as necessary promotes higher level of toxic gases which go to the atmosphere. DESIGN OF TIPICAL FUEL INJECTORS Basically, Fuel Injectors are small electrical solenoids, which are operated by computer and create a

mixture of fuel and air in required quantities at any time of working processes of the engine. Fuel

Injectors are normally oriented between fuel bar and the head of the block of cylinders. The main

difference in design of Fuel Injectors is capacity: how much fuel per second would be sprayed into the

intake system. In addition, for the regular type of the engine it would be good enough that the fuel

injector is operated at frequency of 200Hz, but for the customized fuel injection system the operating

frequency would be few times higher. Normally, the capacity of fuel injectors is measured in cm3/min. STORM TECHNOLOGIES FOR FUEL INJECTION METHODS. Historical review.

About 60 years ago first fuel injection systems where used in some combustion engines. The storm

effect of Rank is well known and was achieved about 150 years ago. First experiments with storm

carburetors were established by Professor Merkulov in 60’s. Mevelopments and research in processes of

storm mixture prototypes known as ECOTOP began in 1994 by the author of this topic. Many inventions

were developed and patented in 1996. The ECOTOP is would be well used in many types of regular engines and turbines, where the capacity and economical values would be increased. ECOTOP means

Economy of Fuel in Russian.

Design of Combined Storm Fuel Injector with Electrostatic Sprayer.

The main idea is how to make Storm Injection Device in easiest way and universal at the same time

where we can use it in any kind of the engine. At the same time we do not really need to reassembly

whole engine for installation of this device. As we found it would be good idea to combine all elements

of the system just in one fuel injector called Storm Fuel Injector. The design of the Storm Injector is

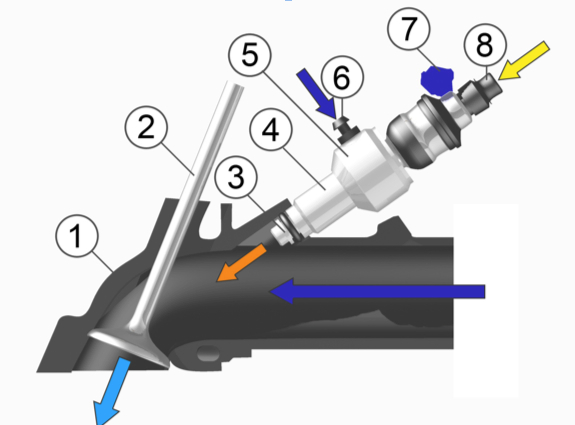

shown on the picture #1 and first real working sample –on the picture#2.

As well known all genus ideas are simple!

Storm Fuel Injector is a very simple device. It contains two elements- Storm Cylinder and Cylinder with

air intake nozzle. Look at the picture#1: 8-fuel injector is placed into intake collector, 6- air storm

mixture element. More details:

1- Intake Collector

2- Intake Valve

3- Head Nozzle of the Injector 4- Storm Fuel Injector (Fuel + Air)

5- Assembled Cylinder of the Injector

6- Intake nozzle for air and water input

7- Standard Power Supply

8- Standard Fuel Injector

We offer to apply progressive technologies related to storm mixture and electrostatic processes

in the way to increase capacity and quality of the mixture. It means we offer to combine

together in the one unit two devices: simple electrostatic sprayer and storm aerodynamic

blender. This unit was established tested and patented. We have all technical documentation for

the manufacturing processes focused for all types of engines and vehicles world wide.

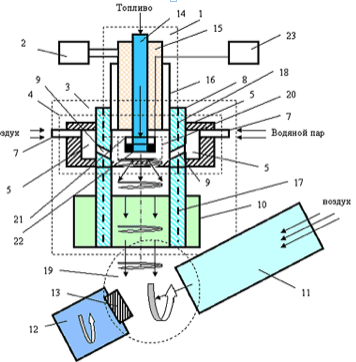

This unique device contain few main sections-parts (see picture 1). It contain fuel injector 1,

electrostatic sprayer 20, storm spray-blender 3, body-holder 10, holes located at some angle 9

(5-6 holes), nut-connector 4.

1- Fuel Injector

2- Operating control unit

3- Storm Sprayer-Blender

4- Outer Sprayer

5- Body of the sprayer-blender

6- Internal Section

7- Chokes

8- Connector

9- Holes (at some angle)

10- Body of the ramp

11- Intake Collector

12- Combustion Chamber

13- Intake Valve

14- Fuel Chanel of the Injector

15- Body of the Injector with the electromagnetic Valve

16- Gasket

17- Internal Troat

18- Outer triat at the connector

19- Zone of the Storm Separation and Blend processes

20- Electrostatic Sprayer

21- Isolator

22- Electrode-Electrostatic Sprayer

23- Power Supply of High Voltage

Electrostatic Sprayer and Fuel Activator

It is simple device. It contain Electrostatic Sprayer 20, contain low energy High Voltage Power Supply 23,

Isolator 21, which is connected to the connector 22 with the conic sprayer (not shown on the picture),

power supply of High Voltage 23 takes power not more then 5-10W with constant current of about 20

kV.

HOW DOES IT WORK The main directions how this device work including two stage processes INTO FUEL SAPARATION

PROCESSES.

This method is achieved by applying the device of electrostatic forces 20 and Storm Sprayer at the same

time of working.

When the solenoid valve is open the fuel goes into the fuel channel 14 with the total pressure of 10 atm.

Air goes into the choke 7 and into the acceleration chamber where it spins and separates the fuel spray,

which also separates by electrostatic nozzle to microscopic fractions and makes excellent mixture. This

mixture has higher efficiency then at regular systems and gives more power and economical results

including higher emission results. AKNOWLEDGEMENTS

1. STORM TECHNOLOGIES ARE VERY PERSPECTIVE FOR PREPARING MORE IFFICIENT MIXTURE OF

FUEL AND AIR

2. STORM FUEL INJECTOR IS A REVOLUTION IN HIGH TECH APPLICATIONS. IT HELPS TO REDUCE

FUEL USAGE AND INCRESE POWER CAPACITIES OF THE INTERNAL COMBASTION ENGINE FOR

MORE THEN 20% AND REDUCE IMISSIONS BY 10 TIMES

3. THE WIDE USE FOR ANY KIND OF TRANSPORT VEHICLE WICH HAS FUEL INJECTION SYSTEMS

SOON WILL REPLACE EXPENSIVE CATALITIC NEUTRALIZATORS. IT WILL SOLVE ECLOGICAL

PROBLEMS AND AIR OF THE ATHMOSPHERE OF OUR PLANET WILL BE CLEANER. ESPECIALLY, IT

IS VERY ACTUAL FOR BIG SITES WHERE IT IS A MOJOR PROBLEM WITH THE AIR POLUTION.

|