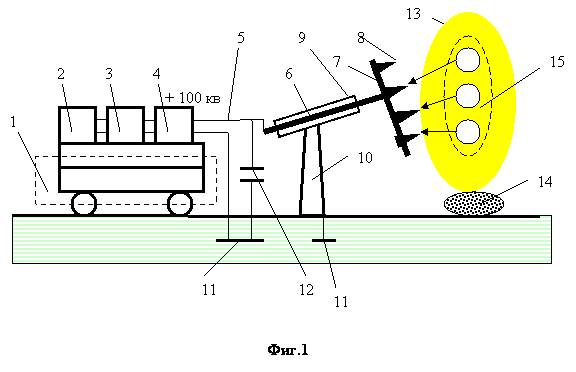

ABSTRACTS ON NEW TECHNOLOGIES 0. Ionosphere elecricity.

The establishment of such non-traditional power due to real abundance of natural electricity near the condenser, and a mechanism of natural renewal of the permanent nature of the ionospheric plasma and the solar wind. This method and device may provide a separate electrical power, great power (hundreds of megawatts) to the regulation withdrawn power, which is regulated by the load, or even the entire civilization, provided the safe placement of such facilities in the uninhabited desert areas, without prejudice to the environment. Maximum capacity of electricity withdrawn from the ionosphere is maximal during the winter months, since the flow of solar wind during this period to the maximum planet. It is clear, fast, noise free and very effective. Ready for production. 1. TECHNOLOGY OF PURE BURNING OF SUBSTANCES

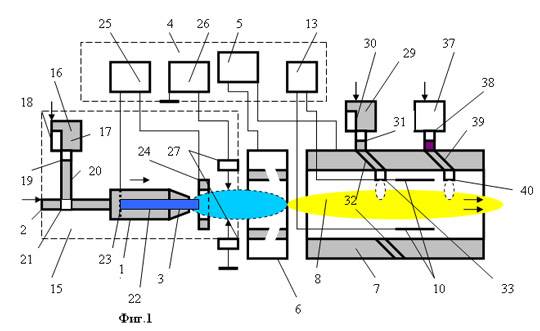

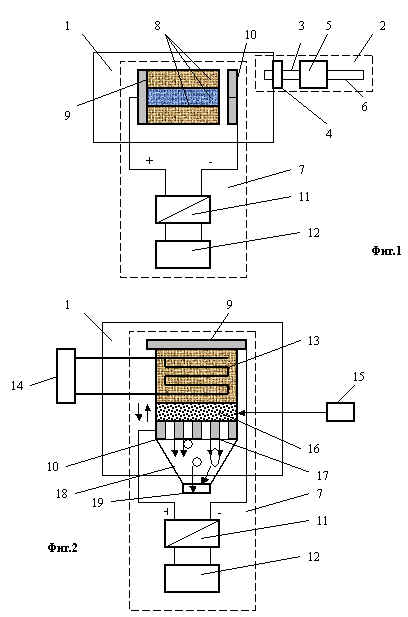

The new physical effect of a significant intensification of burning is discovered at influence on a flame of an electric field of the certain parameters. The new technology based on this discovery consists of management of burning by means of an electric field of the certain parameters. The technology by the current moment has no analogues in the world. However, despite of a seeming simplicity of realization, the physical essence of the given important technology is difficult and is reduced to intensive influence of electric and electromagnetic fields on various processes of burning (power break by an electric field of long circuits of hydrocarbon substance, ozonization of an oxidizer, elimination of a double electric layer on border of a flame, etc.). In case of burning low-grade fuel, luminosity of a flame sharply increases, unpleasant smells (aromatic hydrocarbons) disappear and is sharply, in tens times, toxicity of departing gases decreases.

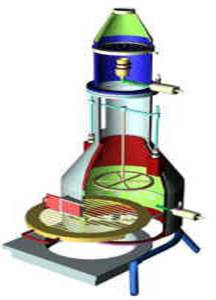

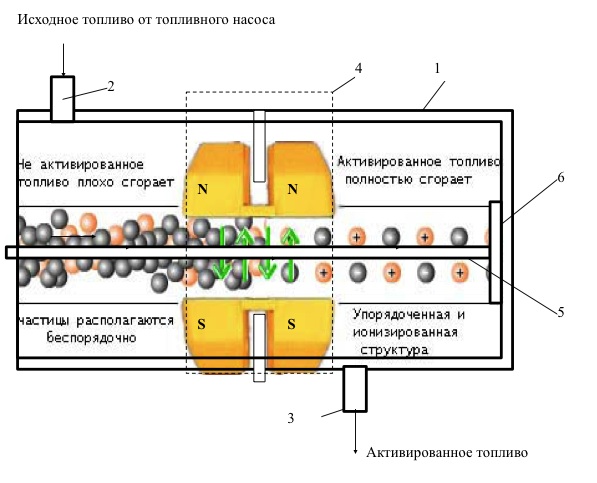

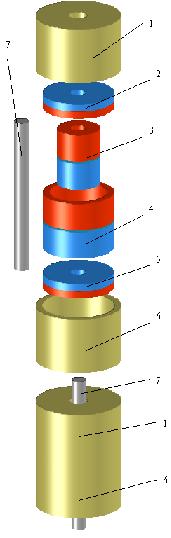

Omnivorous burner  Concerns to burners with the combined fuel. The technical result of these burners consists of improvement of the design leading economy of the basic fuel, the power efficiency, to fuller combustion of all components of fuel and ecological compatibility. The specified technical result is reached by that in the device containing the case of a burner, an entrance fuel pipe and the chamber of combustion, following devices are entered: the activator of a fuel mix with an oxidizer (it is made in the form of a source of an electric field); the activator of burning of a burner of a flame (also it is made in the form of a source of an electric field); devices for preparation of steam and fuel gas; special "whirlwind" devices of fuel, oxidizer, fuel gas, steam and the flame. All listed innovations allow to burn extremely full any hydrocarbon waste and to save the basic fuel considerably and, thus, to raise ecological cleanliness of burning in 10-100 times. 2. ECONOMY OF FUEL The new technology of radical economy of fuel which essence consists in the interconnected application of several physical effects is offered: activation and electrostatic dispersion of fuel; vortical effect of mixing of thin sprayed fuel with air and water steam; intensive ignition of a fuel mix with imposition of electric field on a torch of a flame. Experiments show, that whenthe offered methods of intensification of burning have been realized in full, there is a minimum two-multiple economy of fuel at ideal ecology of fiery process. 2.1. Magneto electric activation of fuel.  The first stage in a chain of actions on economy of fuel is activation of fuel by means of the special device. The technology provides introduction in a fuel path of effective activators of fuel. To realize of this useful innovation design of the fuel filter and the activator of fuel is applied. For this purpose capacity of the fuel filter is transformed into unusual high-voltage electric condenser with liquid dielectric to which fuel serves. The external corps of the fuel filter acts as one of facings of such condenser. Thus the fuel filter is supplied by the source of a magnetic field in addition placed in the fuel filter, and a source of an electric field. This device provides : 20-30% fuel savings, reduction of harmful emissions in 10-15 times, increase engine power up 20%.

2.2. The device of economy of petrol of motor transport - vortical «EcoFuel» (the device of vortical preparation of a fuel mix for an internal combustion engine of petrol motor transport). The simple device of economy of petrol and increase of capacity of an internal combustion engine (ICE) for petrol motor transport is developed and tested. The essence of this technology of homogenization of a fuel mix for any ICE consists in active vortical mixing and crushing of drops of petrol in a vortical stream of the additional air coming through this device from an atmosphere. For carburetor ICE “EcoFuel” is made in the form of thermally isolating insert with vortical atomizers, this insert is placed between the carburetor and inlet collector ICE. For injected ICE «EcoFuel» is developed in two variants - built in an inlet collector and in the form of a separate device. This device provides : 10-20% fuel savings, reduction of harmful emissions in 10 or above times, increase engine power up 10-20%.

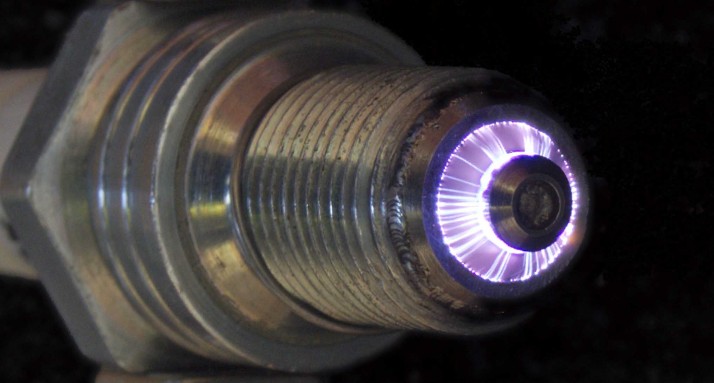

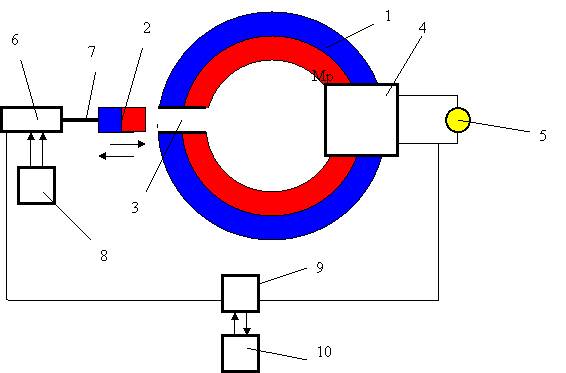

2.3. A magnetic candle with rotation of an electric arch  Finishing part in a chain of process of an effective utilization of fuel is burning fuel which is offered for carrying out with use of candles of a special design - a magnetic spark plug with rotation of an electric arch. The given discovery of effect of rotation of an arch in a magnetic field can be used with success, as in spark plugs, and in plazmatrons of new generation. During submission of an impulse of a high voltage to electrodes of such candle, the electric arch does many turns. As a result of it the process of ignition and burning of a fuel mix in chambers ICE considerably is improved. Such magnetic candle considerably saves petrol in the car and raises «capacity» of ICE. This device provides : 30-40% fuel savings, reduction of harmful emissions in 15 or more times, increase engine power up 20-30%. 3. MOTORS ON WATER-ELECTROHYDROSHOCK ENGINES AND TURBINES Fuel continuously rises in price, therefore views of scientists and inventors are riveted to water for a long time. Their purposes and tasks comprise learning how to use water as a working tool for motors and learning to allocate and transform internal energy of water for fulfillment of useful work. The well known fact, that 2/3 surfaces of a planet are occupied by The World Ocean, hence, there is much water on a planet. The nature has prepared enough water for us. The unique technology is developed for achievement of the extremely useful purposes specified above.  The original technology of transformation of internal energy of water to useful mechanical work - in kinetic energy of rotation of the water motor of new generation is offered. The essence of idea of creation withoutfuel electro water transport with very small consumption of energy is simple enough; it is useful application of electrohydroshock effect of Yutkin. The effective ways and various devices of transformation of energy of electro hydraulic pressure of the water received from the electric discharge in water, by means of electro hydraulic impact into mechanical energy of movement of working body of original electrohydroshock engines (turbine and piston types) are offered.

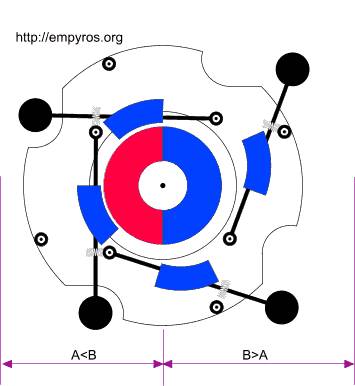

4. THE MAGNETIC MECHANICS AND MAGNETIC POWER ENGINEERING In this section some important inventions in sphere of magnetic mechanics are described. Interesting examples of useful application of constant magnets for creation of contactless magnetic bearings, magnetic reducers and various magnetic engines are resulted.  But the beginning there is some history of a question … The magnet is known already more than three millennia, but its many secrets are not solved yet. Constant magnets (CM) do not lose the properties for centuries. What is the reason of their power interaction and without visible expenses of energy and what is the reason of their "longevity"? Whence and how and what does energy act in them? Many questions on CM have no answers. Constant magnets become more powerful and their huge elevating force, in the ratio weight of a magnet and weight of a cargo lifted by a magnet almost 1:1000, is reached now. The prospect of extraction of inexhaustible internal magnetic energy from constant magnets and transformation of energy into other useful kinds always attract attention of scientists and inventors. Especially the magnetic power and the magnetic mechanics in connection with an aggravation of a global power problem become actually. How do we take, transform and use this energy of constant magnets? Partly this problem was solved in the experimental discoveries by the genius scientist M. Faraday, more than 180 years ago. It is the phenomenon of an electromagnetic induction to find out by him (occurrence of electricity at movement of a constant magnet  concerning the coil of inductance); there were electric generators which applied practically in all power stations of the world. However, electromagnetic generators consume significant mechanical energy for manufacturing of electric power. Is it possible to get magnetic engine and the static magnetic-electric generator of the electric power and if it is possible how to make it possible?

4.1. Contactless magnetic "eternal" bearings  Civilization can’t survive without bearings today. Bearings - a basis of all moving parts of any mechanical devices. However mechanical bearings are subject of rather fast deterioration. Therefore they are insufficiently reliable; they demand constant survey and care (greasing), have the limited service life. New types of the contactless bearing on constant magnets and in the form of the electrostatic suspended internal and external rings-rims of the bearing on the basis of without current sources of a constant electric field are offered. It is simply to carry out such contactless electrostatic suspension bracket or by means of triboelectric effect or by means of new materials-mono-electret. Mono-electret has being already issued for a long time in the form of a thin polymeric film with «soldered in» it by an electric charge of the certain density. Thus "soldered in" electric charge is kept in such film as much as long. Therefore electret film can be used for electrostatic suspension of corpuses. Creation of a new class of contactless bearings is actually and also quite perspective and will bring to investors commercially favorable business.

4.2. Withoutfuel electrogenerators We suggest interested persons to organize manufacture withoutfuel electrogenerators (WFEG) and devices on the basis of their principles of action: power transformers of a direct current, amplifiers of capacity (on force of a current or on a pressure (voltage)), power units on 220 volt  (work long time from one "finger-type" battery), etc. WFEG is a pump, collecting (pumping over) energy from space surrounding us by means of working substance with the subsequent concentration and transforming to the electric power with the parameters necessary to us. There are many possible principles of construction WFEG. For example, we have carried out experiments with WFEG on an electromagnetic principle. Raising a working corpus, it was possible to receive three times more energy, than it has been spent. But, selecting materials for such WFEG, it is possible to achieve a much greater output of the electric power (in comparison with spent). For today we create and successfully test breadboard models WFEG functioning by three various principles (accordingly, three completely various designs): · On the basis of so-called "transformer Tesla" (ТТ); noninductional coil; the amplifier of capacity (both on force of a current, and on a pressure (voltage)). Besides there are two other designs (use of completely other principles) WFEG on which we are conducting works on creation of working breadboard models now: Engine of Hendershot; Adams's engine. After successful end of works on creation of working breadboard models of the specified designs (we plan to finish these works till March, 2009) we are going to start creation of the household devices based on principles WFEG. The commodity market for such devices is huge! The sphere of application is extremely wide: from direct electro supply of objects (including economy up to 90 % of the electric power) up to medical devices (power informational medicine). 4.3. Electric motors without opposite EMF We represent the electric motor without opposite EMF (EMP - electro moving force). Let's consider in details advantage of such electric motor in comparison with existing one today. For simplicity of the analysis we shall take any collector or valve engine. It consists of a rotor and stator. Windings of excitation can be as on a rotor with stator and only on one rotor or stator (if constant magnets of excitation are used). At submission of a voltage on the engine a rotor and stator begin to move relatively each other, thus in windings of an anchor or stator (if the rotor is raised by constant magnets), it is induced EMF, always directed against a voltage of the external power supply. In process of increase in number of turns of a rotor (the valid or seeming linear speed of movement of a conductor concerning a magnetic field of excitation) the current in windings under action of this EMF decreases, accordingly decreases, together with rotating moment. For its increase it is necessary to raise a voltage (power) of a feed of the electric motor. In modern electric motors practically all power brought for a feed is spent for overcoming counteracting EMF. For example, the serial electric motor of a direct current of type 4ПН 200S has following characteristics: power of 60 KWatt; a voltage 440 V; a current 149 A; frequency of rotation 3150/3500 rev/min; efficiency of 90,5 %; length of stator 377 mm; diameter of a rotor of 250 mm, a voltage of losses 41,8 V; a voltage on overcoming induced EMF 398,2 V; power on overcoming of losses 6228 Watt; the rotating moment (3500 rev/min) 164,6 Nanometers. It turns out, that if to get rid from opposite EMF for a feed of the engine a source of a voltage not 440 volt but only 42 volts is necessary, at the same current 150 А. Therefore power consumption at full loading will make 6300 watt at mechanical target power of 60 KWatt. Adjustment of target power of the engine without opposite EMF also can be carried out by change of a voltage of a feed or pulse regulation. The electric motor without opposite EMF consumes many times less electric power, than target mechanical one because it does not arise at rotation of a rotor of a voltage, counter to a voltage of the feed, forcing to increase a voltage of a feed of the engine for reception of necessary power. Variants of construction of similar engines are found, data on interaction of magnetic fields in the similar engines are confirmed practically obtained the theoretical assumption. During carried out experiences opposite EMF was absent, that allows to approve an opportunity of creation of the efficient engine under offered schemes. 5. FAST DRYING OF POROUS MATERIALS Importance of technology of drying (as well as labor input and power consumption of these processes) of porous materials (for example, bricks and wood) is well-known. Various technologies of drying of porous materials are known and are applied: thermal, vacuum, etc. However  complexity of the equipment and great power expenses essentially complicate technological process of drying, reduce quality and efficiency of drying and, hence, lead to rise in price of finished goods of set humidity. It is offered unique (with small power expenses) effective technology of high-speed drying of porous materials which is based on the known phenomenon electric osmosis.

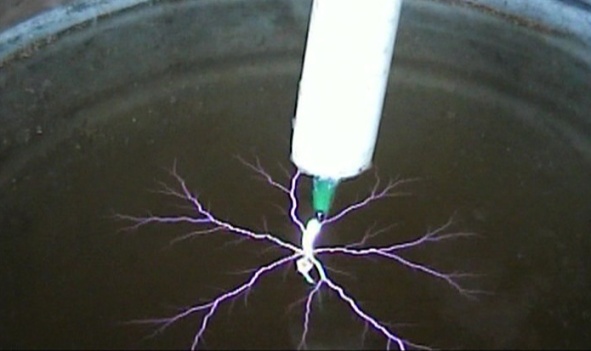

6. ELECTRIC SUPPRESSION OF FIRES Fires are terrible acts of nature and annually put enormous losses of a civilization and, that the most important, ruin the nature. The fire service exists in the world more than 300 years. However for so long period of existence and development, it has not undergone radical modernization. Till now everywhere in the world fires are extinguish by foam and by water that is rather inefficient. In a number of cases, for example for frequent forest fires and for fire suppression in multi-storey structures well known methods are inefficient in general. Well known methods of fire suppression do not allow to extinguish a flame instantly and, especially, to prevent ignition. But there is an output! There is an idea of the original decision of all these problems of fire suppression approved in practice on the basis of own discovery.  The new revolutionary technology of contactless fire suppression of any complexity approved on experiences, based on influence on a flame of a strong electric field of the certain parameters is offered to joint development and introduction. This is paradoxical simple and unusual electrophysical technology; it is directed on elimination of the centers of chain reactions of division of hydrocarbon radicals of burning substances in a flame. This technology is rather simple in realization. For its realization the mobile means, containing only two electrodes (one of which sliding) and rather low-power pulse source of a high voltage of the direct current, attached to these electrodes are necessary. The physical essence of this technology concludes that the electric field of the certain parameters actively oppresses and extinguishes a flame, and electrons of chain reactions of burning of substances are spasmodically eliminated from a flame by special needle devices on which submit cyclic impulses high-voltage positive electric potential of the certain parameters depending on parameters of burning of a flame then the flame goes out jump for shares of a millisecond. The technology is recommended to mass introduction. 7. ECOLOGY AND NEW ECOLOGICAL TECHNOLOGIES A worsening Global Ecology is one of the sharpest problems of the present. The basic fault of global pollution of practically all inhabitancies on the Planet is imperfection of technologies. Some technologies connected with their wide circulation (especially fiery technologies) bring the maximal contribution to pollution of atmosphere (to 70-80 %). For this reason the developed electronic fiery technology of pure burning of fuel and waste in high-voltage electric  fields of low power has huge value for the decision for global economic clearing of atmosphere on a planet and should be used everywhere in all fiery technologies (motors of transport, power system, etc.). Its wide introduction will allow in the shortest terms to improve ecology of atmosphere of cities and all planet essentially. Below abstracts on application of this technology for ecologically pure electronic fiery recycling waste are resulted. 7.1. Electronic fiery technology of ecologically pure burning of oil torches (OT) The problem of toxic oil torches is sharp enough not only for Russia. We suggest to make their pure for ever. By extremely simple and cheap way. We offer effective (with small power expenses) and a simple way of pure and intensive burning of toxic oil gases - residual products of oil refining. The essence of idea is simple. Burning of oil gas should be spent in an electric field. In this case the oil torch becomes ecologically pure.  The way is checked up experimentally and patented. And though the way is simple, at its practical realization there are many features (know-how). Real experiments confirm its ecological efficiency. Owing to powerful ionization of flame OT in an electric field and ozonization of air’s layer in a zone of burning, the intensity of burning of a flame and completeness of burning increases in some times sharply. 7.2. Ecologically pure electronic fiery recycling of toxic waste (petroleum slimes) The essence of the given technology consists in realization of operated effective burning a flame of burnt toxic waste (for example, petroleum slimes) in the special electrified furnace by means of an electric field of low power of the certain configuration and parameters. The electric field makes process of burning of toxic waste more active, and allows splitting up radicals of burning toxic substance effectively. As a result the process of burning is accelerated in tens times and proceeds ecologically purely. In such electrified flame substances and components (even such which at usual burning are not ignited) burn down practically all! For example, toxic oxides of the carbon, containing in departing gases of products of burning, are oxidized up to carbonic gas, dioxides are not formed in general, after burning there is a minimum of nontoxic ashes, and only water steam and carbonic gas are released to atmosphere. The technology of burning of any toxic waste is checked up experimentally. There are test reports, patents and numerous publications. 8. WATER AND ITS ECOLOGICAL REFINEMENT Ecological refinement and disinfecting of water (sewage and potable water) are the major problems of ecology. Various technologies are known and are widely applied: mechanical filtering, chlorination, ozonization of water, bioclearing, etc. Last time cavitation technologies of water treating (in particular, sewage) start to be applied. However, despite of progressiveness of these cavitation technologies, their development is  constrained by high power expenses and complexity of cavitation devices. The unique cavitation technology of refinement and disinfecting of water with use of electro-hydroshock effect of Yutkin is offered. Its essence concludes that the series of cyclic short-term powerful hydro impacts in processable water are created by transmission of electric categories of the certain parameters from the special electric device concerning low power. As a result there is an intensive disinfecting and water treating. Thus processing of water occurs in great volumes at once and with extremely small consumption of energy. The technology is patented and checked up experimentally.

9. HYDROGEN RECOVERY.

Method and devices of direct electrochemical decomposition (dissociation) of water and water solutions into hydrogen and oxygen by transmitting electric current through water are well known. Their major advantage is simplicity of implementation. Main drawbacks of the device-prototype – hydrogen generator- are: low productivity, considerable energy consumption and low coefficient of efficiency. Theoretical calculation of required electric power necessary for recovery of 1 cubic meter of hydrogen from water amounts to 2, 94 kWt/hour. This hinders for the time being using this method for recovery of ecologically clean fuel for transport. |